Precision CNC Metal Fabrication Services

Precision sheet metal fabrication, plate, and structural fabrication involve a variety of processes to produce a finished product. Some shops only specialize in one or two processes, leaving you to deal with multiple design, engineering, fabrication, and manufacturing companies. Working with multiple vendors makes it more difficult to manage quality, along with increasing costs and lengthening your turnaround time.

Metal Fabrication Solutions from Simple Parts to Complex Weldments and Assemblies

Andersen Industries has the industrial fabrication experience you're looking for in a precision metal fabricator. With our Southern California state-of-the-art, 110,000 square foot facility we are able to serve many markets like construction equipment, heavy industrial, refrigeration, power generation, transportation, and more. We are equipped with a wide range of CNC fabrication-specific equipment allowing us to meet the variety of demands and tolerances for fabricated metal products required by today's manufacturers, OEMs, and construction contractors.

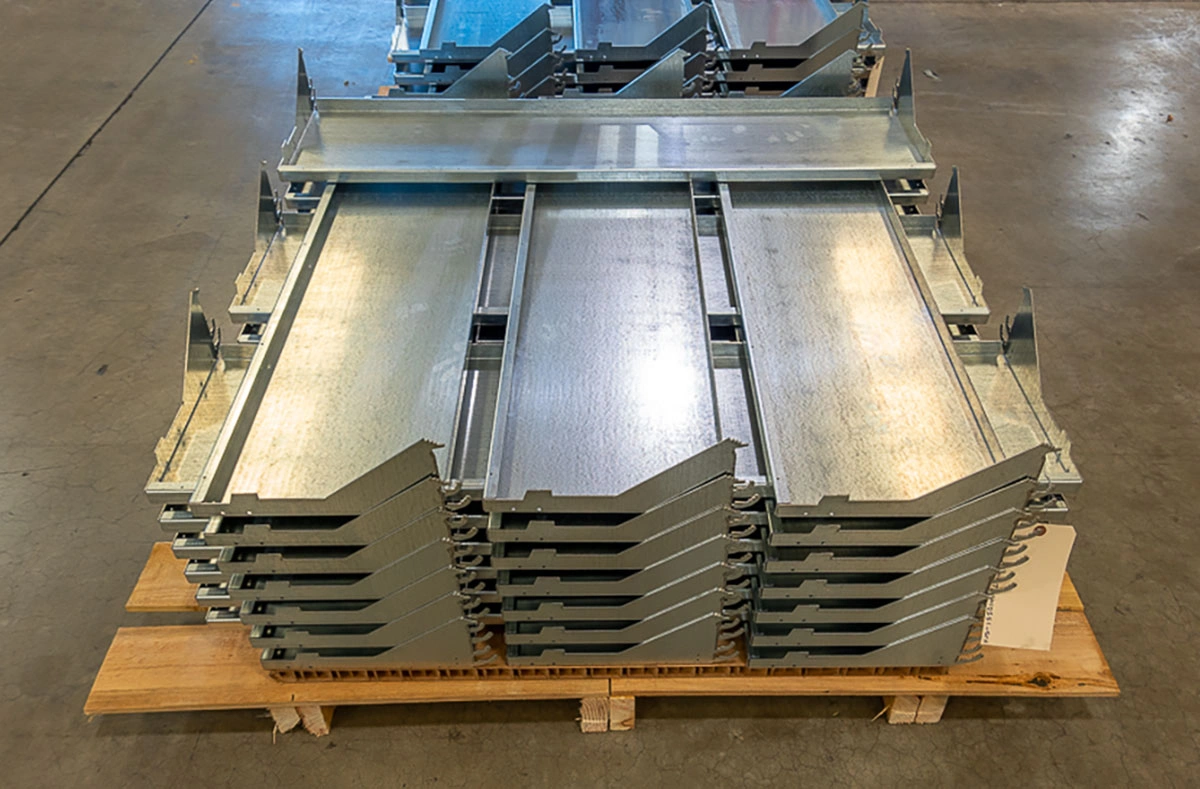

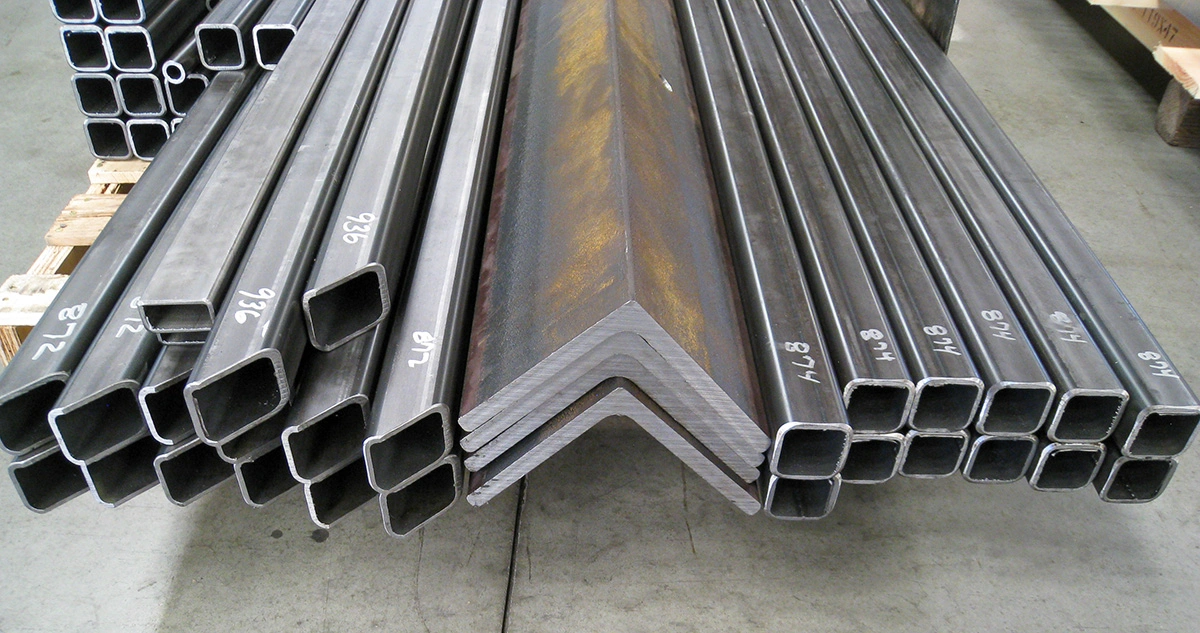

Andersen Industries provides precision sheet metal, plate, and structural metal fabrication to Manufacturers, OEM’s and the Construction industry. We create custom metal parts, weldments, and equipment made from sheet, plate, bar, tube, pipe, and structural shapes in Carbon Steel, Stainless Steel, and Aluminum.

Job Shop and Contract Manufacturing fabrication services include:

- CNC Laser Cutting

- CNC Plasma Cutting

- CNC Turret Punching Sheet Metal

- CNC Turret Punching Plate

- CNC Bending and Forming

- CNC Sawing

- CNC Rolling - Sheet & Plate

- CNC Rolling - Angle, Bar, Tube & Pipe

- Welding

- CNC Machining

When you work with Andersen, you can count on receiving high-quality, long-lasting products and components. Visit our photo gallery to see examples of our work.

CNC Laser Cutting

Laser cutting is a precise thermal process. It delivers high repeatability and accuracy, making it ideal for producing parts that require tighter tolerances. Laser cutting generates the smallest Heat Affected Zone (HAZ) among all thermal cutting processes because it applies heat to a very small area.

CNC Turret Punching and Laser Cutting - Sheet Metal

CNC turret punch/laser machines combine punching and laser cutting in the same machine. With punching speeds up to 400 holes per minute, it is much faster to punch than to laser cut. Typically hole diameters up to 4-1/2” in diameter are punched. Larger diameters and cutouts along with part perimeters are cut with the laser. The equipment we use delivers unmatched productivity and scratch-free processing of complex sheet metal parts, including forming and tapping operations.

CNC Turret Punching and Plasma Cutting - Plate

CNC turret punch plasma machines combine punching and plasma cutting in the same machine. This machine punches small holes up to 3” in diameter in plate faster and more accurately than plasma cutting only. Plasma cutting uses a mixture of gases in order to create the cut. Plasma cutting generates an intermediate Heat Affected Zone (HAZ). Larger holes and cutouts are plasma cut. This equipment provides highly productive contouring with a high-quality dross-free cut. Additional punching processes include coining and countersinking.

CNC Press Brake Sheet Metal Bending and Forming

CNC press brakes take flat sheet metal or plate blanks and form or bend them into various shapes with precision and accuracy. The process requires minimal tooling and is compatible with thick metals and long pieces. Our precision CNC Press Brakes are equipped with multi-axis CNC controls and European Style tooling, enabling us to make fast setups and parts with consistent bend accuracy.

CNC Sawing

CNC sawing equipment delivers high output while producing tight tolerances. This type of CNC metal fabrication equipment uses computer controls to quickly produce dimensioned parts while maintaining the high precision needed for complex shapes. We saw cut bar, tube, pipe, and structural shapes from carbon steel, aluminum, and stainless steel in parts up to 60 feet long.

Plate Rolling, Angle Rolling

Plate rolling takes flat sheet or plate blanks and rolls them into a round, conical, or custom shape.

Angle Rolling takes straight lengths of Angle, Bar, Channel, Tube, and Pipe and rolls (bends, forms them) into round rings.

Contact Us for Custom Sheet Metal Fabricating and Heavy Metal Fabricating

For decades, manufacturers and OEMs have trusted Andersen Industries as their CNC machining, metal fabrication, and welding provider. We have the expertise and capacity to handle projects of all sizes and maintain high quality standards to deliver exceptional results. Send us a message to discuss your sheet metal fabrication project!

Request a Metal Fabrication Quote