WeldPro 360 LRW-18P MIG Welding Boom Arm

The WeldPro 360 LRW-18P MIG Welding Boom (425663) reduces non-arc time for welders, allows you to work right up next to its base, and minimizes shop floor clutter and trip hazards. Easy movement of the welding boom makes repositioning it possible with one hand. Weld settings and controls are within reach of the operator, saving trips to the welder for every setting adjustment. The primary arm rotates 192° around the pivot point, providing complete welding coverage within a 56’ diameter semi-circle welding zone when using a 15’ MIG welding gun. Create clean and organized welding cells by routing hoses and cables within the LRW-18P’s welding arm—no more dangling cables or cords hanging from the arm or laying on the shop floor. The welding arm’s main pivot assembly mounts to your existing building column, a free-standing Floor-Mounted Column or an easy-to-relocate Mobile Base.

Benefits

Increase Welding Productivity

- Quickly move from weld to weld

- Faster adjustments of weld settings by putting controls where operators work

Maximize Shop Floor Use

- No dead zones in the coverage area

- Clean, organized welding cell eliminates shop floor clutter

Improve Welding Experience & Safety

- Trip hazards are reduced by effective cable and hose management

- No strain on users from moving heavy welding carts

Features

- Compatible with welders and both single and dual wire feeders from major manufacturers, including Lincoln, Miller, ESAB and Fronius

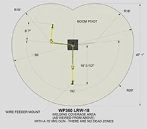

- Primary boom arm has 192° range of motion

- Secondary boom arm has 360° range of motion

- Welding Reach - 56' diameter semi-circle from the boom arm pivot point, with a 15' MIG welding gun

- Maximum welding height of 15’ with a 15' MIG welding gun

- Remote-controlled horizontal adjustment of primary boom arm

- Manual horizontal adjustment of secondary boom arm

- Conduit liner works with .035-.065 wire

- Durable Powder Coated Finish

- UL Listed Electrical Components

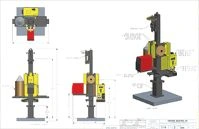

Specifications

Please note that product specifications are subject to change as we continuously improve our products.

- Primary Arm Length: 10'

- Secondary Arm Length: 8'

- Weight: 400 lbs.

- Wire Feeder Capacity: 120 lbs.

Operating Requirements

- Voltage: 120V

- Compressed Air: 90 PSI

Boom Mounting Options

Welding Equipment Accessories

Welding Power Supply Mount

Compatible with major brands like Lincoln, Miller, ESAB, and Fronius

Gas Cylinder Mount

Safely secure inert gas

Bulk Wire Mount

Compatible with wire drums and wire crates

Wire Spool Enclosure

Compatible with spools up to 60 lbs.

Additional Resources

Want to know more about LRW-18P MIG welding boom arms?

Contact us for pricing, product questions, or help configuring the right boom system for your operations. We will respond promptly to provide the information you seek.

Request More Info

Brochure

Brochure Options & Specs

Options & Specs  Coverage Area

Coverage Area